Stakeholders have said that unless conscious efforts are made to revive and reposition the real sector, Nigerian manufacturers will not be able to compete.

The manufacturers said they are being exposed to an unfriendly business and operating environment which they say makes production costs very high and are faced with constant pressure from imported items.

They said unless efforts are made to reduce the cost of local production, the country will continue to rely on imports for the most basic things with its products unable to compete globally.

Growth in Nigeria’s manufacturing sector slowed to 1.49 per cent in the first quarter of this year, owing to worsening FX scarcity, shrinking consumer spending and high borrowing costs. Data from the country’s GDP report shows that growth in the sector saw a marginal decline of 0.12 per cent on a year-on-year basis from a 1.61 per cent growth rate recorded in the first quarter of 2023 to 1.49 per cent in the corresponding period of 2024.

A former Manufacturers Association of Nigeria (MAN) chairperson, Apapa branch, Frank Ike Onyebu, expressed concerns, adding that production costs are rising further, as many manufacturers are running at zero profit, cost or even a loss, just to remain in business. He said despite this, they find themselves having to increase the cost of goods just to keep the lights on.

“How do we compete with goods from other countries that their government is giving them one-digit loans, less than five per cent, to mass produce at any capacity and they are not faced with the numerous problems we manufacturers face here in Nigeria? The challenges are unending; just when you think you have tackled one somewhat, an even bigger one arises. In the good old days, we were making just marginal profit but now, I can tell you for free that we are making nothing and it is passion and the desire to not see our investments fail that is keeping most of us here. We cannot even compete with our neighbours in West Africa; forget about the rest of Africa. How then do we want to export globally?

“There is no power, alternative energy is very expensive, and infrastructure is non-existent. The reason Chinese goods do so well here is because they are affordable for most people. Local manufacturers here can produce these same items at scale but where is the support and room for growth? Instead of support, all we get are obstacles, problems and hindrances from all sides,” he lamented.

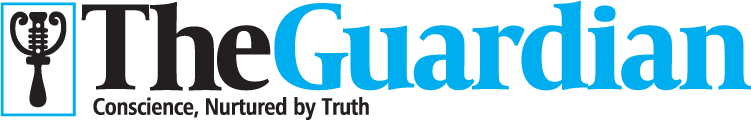

The Chief Executive Officer of the Centre for the Promotion of Private Enterprise (CPPE), Muda Yusuf, said competitive manufacturing is about the quality of infrastructure a country possesses, which is currently in a poor state in Nigeria.

“Competitive production is about the quality of infrastructure and if you look at the state of our infrastructure today, manufacturers cannot be competitive,” it said.

He stated that the high dependence on imported raw materials by manufacturers is another factor that has made local production’s competitiveness low as it exposes them to FX shocks.

3 months ago

4

3 months ago

4

English (US) ·

English (US) ·