Despite investing $6.5 billion over the past 15 years into the steel industry, Nigeria imported $271.96 million worth of iron and steel in 2023.

This substantial expenditure has yet to mitigate the country’s reliance on foreign steel, reflecting ongoing challenges in the industry.

The Nigerian steel sector, with an estimated deposit of 3 billion tonnes of iron ore, has struggled with underperformance and insufficient capacity to meet domestic needs.

Government-owned plants like Ajaokuta Steel Company and Delta Steel Company have faced numerous challenges, including inadequate funding, mismanagement and lack of maintenance.

According to the United Nations COMTRADE database, shows that in 2023, Nigeria imported $271.96 million worth of steel products, a significant portion of its total import bill, Nigeria’s steel import bill remains high, underscoring its dependence on international suppliers for industrial and construction materials.

In 1967, Soviet experts conducted a feasibility study for a Nigerian iron and steel plant under a technical cooperation agreement with the USSR.

Following positive reports on iron ore and coal deposits, a 1970 contract with Russian company TYAZHPROMEXPORT (TPE) aimed to further investigate these resources.

Despite reaching 98% completion in 1994, Ajaokuta Steel has yet to produce steel. The integrated plant was envisaged to have multiplier effects on all sectors of the Nigerian economy such as the industrial, agriculture, transport and construction sectors, among others.

The Ajaokuta plant was designed to produce 1.3 million tonnes of steel annually in its first phase, expanding to 5.2 million tonnes in subsequent phases. It was expected to have significant economic benefits across various sectors and provide thousands of direct and indirect jobs.

The steel plant complex also has a highly sophisticated assemblage of 43 different plants made up of a web of complex iron, cable and machinery of different sizes and functions. Ajaokuta steel has the capacity to become a major producer of industrial machineries, auto-electrical spare-parts, shipbuilding, railways and carriages.

The steel plant’s first phase has the capacity to provide direct employment for 10,000 technical staff and indirect 500,000 for unskilled upstream and downstream employment if it is in operation.

At least $6.5 billion have been spent into the sector. According to data from Federal Ministry of Mines and Steel Development, and the National Bureau of Statistics,

However, despite investments of $6.5 billion, there has been little progress. Data from the Federal Ministry of Mines and Steel Development and the National Bureau of Statistics detail these investments over the years, with no substantial impact on steel production.

2009: $500 million for investment in Ajaokuta Steel Company’s rehabilitation; 2010: $300 million for investment in Delta Steel Company’s expansion; 2011: $200 million for investment in National Iron Ore Mining Company’s exploration; 2012: $400 million for investment in Jos Steel Rolling Company’s modernization; 2013: $350 million for investment in Katsina Steel Rolling Company’s upgrade; 2014: $450 million for investment in Oshogbo Steel Rolling Company’s expansion.

Others are, 2015: $500 million for investment in Metallurgical Training Institute’s development; 2016: $300 million for investment in National Steel Raw Materials Exploration Agency’s research; 2017: $400 million for investment in Ajaokuta Steel Company’s completion; 2018: $350 million for investment in Delta Steel Company’s modernization.

And, 2019: $450 million for investment in steel industry development; 2020: $500 million for investment in steel sector revitalization; 2021: $550 million for investment in steel industry expansion; 2022: $600 million for investment in steel sector growth; 2023: $650 million for investment in steel industry development.

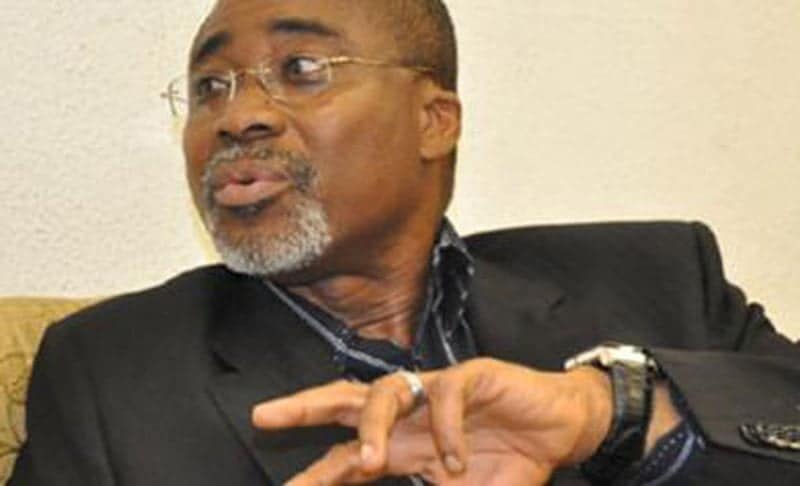

The Head of Department of Geology, University of Ibadan, Prof. Gbenga Okunlola, highlights Nigeria’s potential for steel self-sufficiency.

He advocates for creating a conducive environment for private sector investment and revitalising Ajaokuta Steel.

He said: “I think Nigeria imports more of the steel that we need now. And Nigeria can actually be self-sufficient in steel production. Three things to do. One, we have the raw materials here. Iron ore, we have even the carbonates, the refractories to produce the metal.

“If a Ajaokuta Steel had been functioning, we wouldn’t have any needs. We would have filled some of the gaps. And then we have some of the steel companies and some are just coming up now. Also we have Dangote who wants to go to steel, because he knows that the raw materials are here.

“And not only can we stop importation in Nigeria, we can even supply and export to other West African countries. The resource of the iron ores that we have in Nigeria is huge, we have no less than about 10 iron ore deposits around one location that are world class, not just Itako.

“We have an abundance of iron ore deposits in locations such as Koton Karfe, Agbaja, Jabaniku, and several others in the vicinity, boasting high concentrations of over 40% FeO. Additionally, we have ample carbonates and refractory materials, providing a rich resource base for steel production.

“Nigeria has no business importing steel if we take it seriously. So, what we need to do is to sensitise the private sector and create a conducive atmosphere where they can do manufacturing. Like Dangote companies and others. Right now most of the steel that we produce in Nigeria is from scrap metals. And that is not sustainable.

“So, it’s important that we look inwards, and see how we can rejuvenate Ajaokuta Steel because it is taking too long. So, we need to do something about this, if Ajaokuta Steel starts producing, with the other private steel companies that are coming on then we will be okay. A nation that is self-sufficient in steel will soon be an industrialised nation. That is very important and Nigeria can be part of those nations.”

The former Delta Steel Company (DSC) being managed by Premium Steel and Mines Limited

The former Delta Steel Company (DSC) being managed by Premium Steel and Mines LimitedHe noted that Nigeria’s geoscience industry has a long history of producing highly skilled professionals, with thousands of geoscientists trained since 1960. Many of these experts were trained in Russia in the 1970s and 1980s and are still active in the field. Adding that Nigerian universities, such as the University of Ibadan, have been training PhDs and MScs in geology and metallurgy for African countries through the Pan-African University of Life and Art Sciences.

He further said: “When Ajaokuta steel was non-functional, other steel companies were coming up even though their production may be low. So for us to say we don’t have the capacity is not enough. But of course, we are living in a global world where we need to integrate technologies and all that.

“But to say we don’t have capacity is not true. For example, the Parliament of Geology university of Ibadan, we run the program for the African Union, Pan-African University of Life and Art Sciences, where we train PhDs and MSc for African countries and we have trained students from over 46 African countries.

“In Ibadan, in the last six years, we have produced over 40 PhDs in the art science program. We know we have produced over 20 PhDs, between 2023 and 2024 we have produced seven PhDs from different African countries. So we even train Africans. So for people to say we don’t have the capacity is not really good.

“We know there can always be development, but we have it. There are good metallurgists that have been trained over the years, but because they don’t even know where to practise, they are elsewhere. So we can harness them. And even if you say they are okay because they have been out, it takes just a few months to rejiggle their expertise, and then they float.”

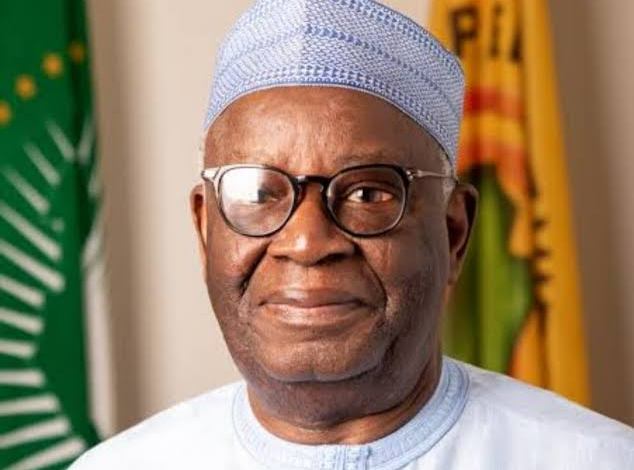

Professor Agajo from the Federal University of Technology, Minna, underscores the urgent need for steel industry revitalization to support Nigeria’s industrialization.

He criticises the government’s lack of commitment and the neglect of the near-complete Ajaokuta Steel plant.

He lamented that the Ajaokuta Steel Company, which was nearly 90% complete, was left to decay, with parts stolen and overgrown with grass. Said that revitalising the steel industry is essential for Nigeria’s industrial advancement, as it will reduce reliance on foreign exchange and enable domestic production of raw materials.

While speaking on the steel sector development, he said the country’s abundant iron ore deposits, particularly in Itakpe, Ajaokuta, Aladja, and Kasina, provide a solid foundation for a thriving steel sector. Adding that the government commitment is lacking and hindering the industry’s growth.

He said: “The problem we have is the government’s commitment to develop the steel sector. We had an Ajaokuta steel company that was actually up and doing close to 90 per cent completion but we squandered that opportunity when we refused to complete it.

“Today it has been overgrown by grass, most of the parts are stolen. Not until we return to that era, where we will develop our steel manufacturing company to serve us as the materials in the area of manufacturing. We will still be running within a cycle.

“The development of raw materials is actually dependent on the viability of our steel industry. So the steel industry needs to be working and it will produce and by doing it will only save us this issue of foreign exchange. Some of these things will now be imported, will now be gotten and acquired right in our soil which is an advantage to the nation.”

He said that Nigeria’s economy is in dire need of a boost, and revitalising the steel industry is crucial to achieving this goal. “We are spending money on what we have. When you’re spending money on what we have, that is more or less like wastage. If what you have is here, all you just need to do is to harness it and translate it to what you want to use it for.

“That money will be saved and probably be used to take care of other sectors of the economy. But if you complain that you don’t have enough and out of what you don’t have enough you are still spending it on importation, the country goes poorer.

“If we can develop this sector so many countries will declare interest to come and buy from us and that will be using it to make foreign exchange and put less pressure on the oil because oil is the source of our economy now. We have an additional input when it comes to generating foreign exchange for the country, generating revenue for the country but as long as it’s like this we will just be running a race within the cycle.

“There needs to be a mass action from the government. This is a government that preaches and equally presents itself as a government of renewed hope. Some people must have lost hope but the tag of the government is renewed hope. So please, there should be massive investment in these areas to revive these steel complexes, steel infrastructure and mining areas like the Itape Iron Ore to make sure that these things start again.

“And equally throw away government interest. This is not politics. This is reality. Nigeria is in dire need of sectors like this to help balance its economy. All of us know the situation we are in now. A country that is seriously on borrowing as we speak needs things like this to stabilise.

“So the government needs to revive these industries to make sure that these processes are running and the country will make gains, earn more money, earn more foreign exchange and our Naira will get its value again.”

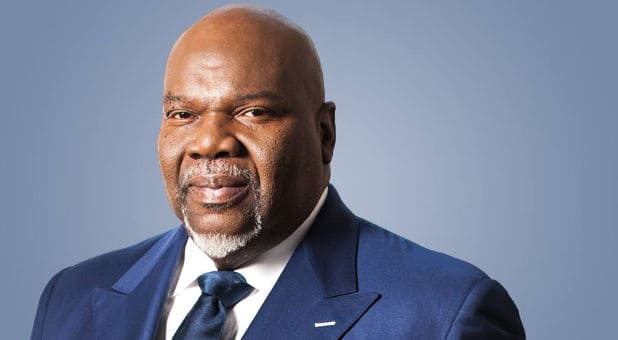

Minister of Steel Development, Prince Shuaibu Audu, acknowledged the need for over $2.5 million to fully revive the steel industry. He is negotiating with foreign investors to establish a new steel plant and revive the Light Steel Mill for iron rod production.

Audu said, “We plan to revive the Light Steel Mill for iron rod production, costing about N35 billion. Discussions are ongoing with defence and interior ministries to use DICON for military hardware production.”

The current state of Nigeria’s steel industry reveals a critical need for effective policy and investment. Revitalising the sector could reduce import dependence, boost economic growth, and stabilise the naira.

The government must prioritise substantial investments and strategic partnerships to realise the potential of Nigeria’s steel industry and ensure sustainable industrial development.

3 months ago

83

3 months ago

83

![[ICYMI] No N500m missing from customer’s account, says Access Bank](https://cdn.punchng.com/wp-content/uploads/2018/09/14183604/20180707-DSC_0077new.jpg)

English (US) ·

English (US) ·